Table of Contents

Introduction

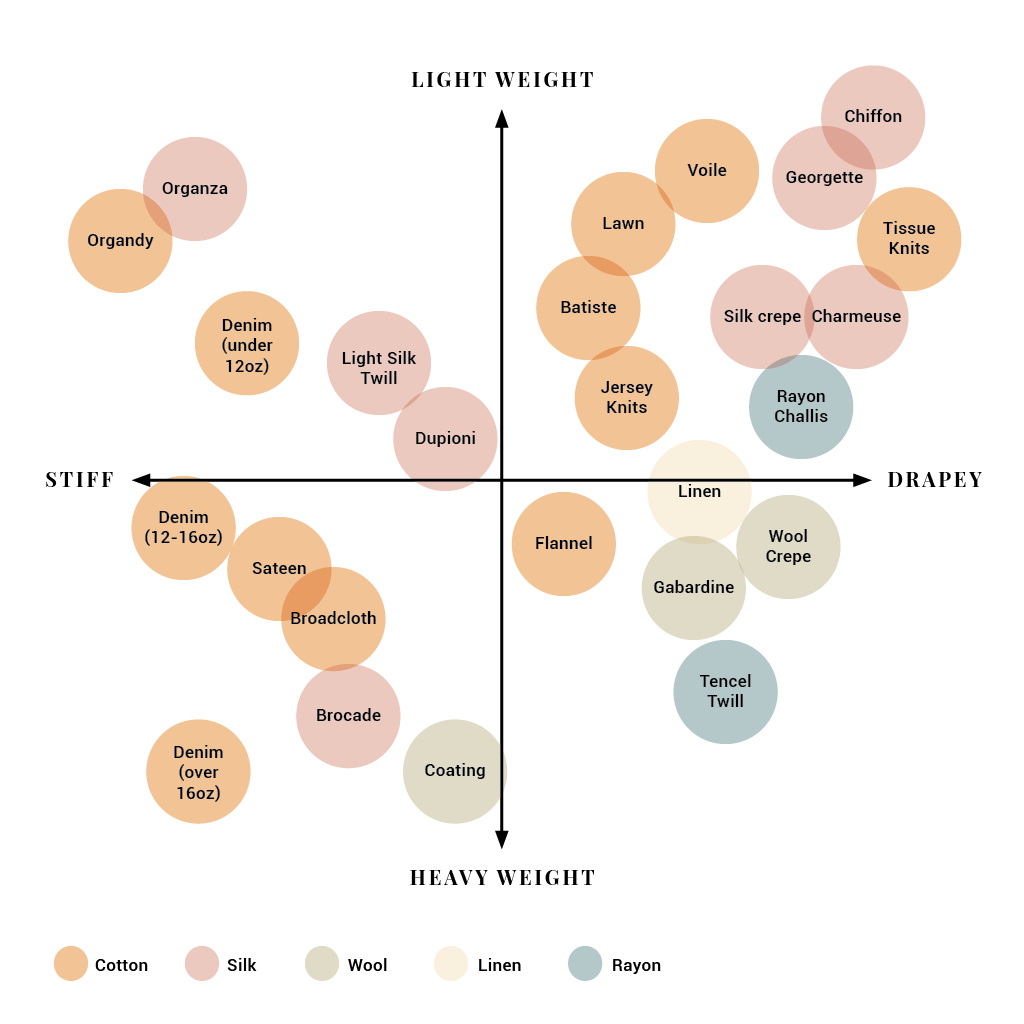

When planning a digital printing project, choosing the right fabric weight is just as important as selecting your design. Fabric weight, often measured in GSM (grams per square meter), affects the look, feel, and durability of your printed textile. If you’re new to the process, you can explore our Custom Fabric Printing service to see how different fabric options perform. Understanding the difference between fabric gsm for printing and fabric weight for custom printing will help you achieve the best results, whether you are a small business, independent designer, or DIY crafter.

What Does Fabric Weight (GSM) Mean?

Fabric weight, measured in GSM, tells you how heavy or light a fabric is. The higher the GSM, the thicker and denser the fabric. For example:

120 GSM Cotton Voile → lightweight, soft, and semi-sheer

300 GSM Cotton Canvas → thick, durable, and structured

GSM directly impacts how the fabric drapes, breathes, and absorbs ink during digital printing. If you want a deeper dive into how GSM is defined across the textile industry, check out Textile Exchange’s guide on Understanding GSM.

Why Fabric Weight Matters in Digital Printing

Print Quality – Lightweight fabrics may allow colors to look softer, while mid- to heavy-weight fabrics can produce richer tones and sharper detail.

End Use – A 120gsm fabric works well for scarves, but won’t hold up for tote bags.

Durability – Heavier fabrics last longer and resist wear, making them ideal for upholstery or bags.

Cost & Sustainability – Lighter fabrics use less raw material and may be more eco-friendly for short-term products.

Common Fabric Weight Ranges for Digital Printing

Lightweight Fabrics (70–150 GSM)

Perfect for scarves, lining, blouses, and delicate prints

Provides a soft drape and breathable finish

Example: Cotton Voile 120gsm for summer wear

Medium Weight Fabrics (150–250 GSM)

Versatile for everyday garments like T-shirts, dresses, and sportswear

Balances print clarity with comfort

Example: Organic Cotton Jersey 180gsm for custom T-shirts

Heavy Weight Fabrics (250 GSM and above)

Best for canvas, upholstery, banners, and tote bags

Ensures vibrant print and strong durability

Example: Canvas 280gsm for custom printed tote bags

How to Choose the Right Fabric GSM for Printing

When deciding on fabric gsm for printing, consider:

Purpose of the fabric: clothing, home décor, or promotional use

Design complexity: fine patterns may need denser fabrics for sharper results

Longevity: lightweight for seasonal fashion, heavier weight for durable goods

Customer expectations: comfort, transparency, or stiffness

👉 For an overview of printing styles and their compatibility with different weights, visit our Digital Fabric Printing Methods guide.

Tips for Designers and Small Businesses

Always order swatches first to see how your design looks on different weights

Check shrinkage and transparency – especially for lightweight fabrics

Communicate clearly with suppliers – specify GSM and fabric type when placing orders

(External link: Threads Magazine – Fabric Weight Guide)

Case Studies & Examples

120gsm Cotton Voile for Summer Shirts

Soft, breathable, perfect for fashion lines targeting warm climates.

180gsm Organic Cotton Jersey for T-Shirts

Popular for small business apparel printing; balances cost and durability.

280gsm Canvas for Eco Bags

Heavy-duty, sustainable choice for promotional merchandise and retail.

👉 Before bulk ordering, compare options on our Order Fabric Swatches page.

Conclusion

Choosing the right fabric weight for custom printing ensures that your designs look professional, last longer, and meet customer expectations. Whether you’re printing a lightweight scarf, a mid-weight T-shirt, or a heavy canvas bag, understanding fabric gsm for printing helps you make the best decision.

✅ Call-to-Action

👉 Ready to test your designs?

Order Swatches to compare fabric weights before you print.

Get a Quote for your next custom fabric project.