Table of Contents

Introduction

For small businesses, one of the hardest challenges is not creativity—it’s cost and inventory risk. You may have a great idea for a new collection, but ordering thousands of meters of fabric upfront is simply not realistic. This is where fabric printing for small business becomes a game-changer.

With low minimum order quantities (low-MOQ), you can create your own unique fabrics without tying up all your cash flow in inventory. Custom and wholesale fabric printing also allow you to test new designs quickly, build a recognizable brand identity, and scale production only when demand is proven.

In this guide, we’ll cover why fabric printing matters for entrepreneurs, the difference between wholesale and small-batch printing, how to choose the right partner, the benefits for small brands, and a step-by-step roadmap from swatch to bulk order.

Why Fabric Printing Matters for Small Businesses

Stand out with unique designs

Big brands can flood the market with mass-produced items. Small businesses, however, win through differentiation. Custom fabric printing lets you develop one-of-a-kind patterns, limited editions, or seasonal designs that make your products instantly recognizable.

Strengthen brand identity

Consumers connect with brands through visuals. A signature print can help customers remember your label. For example, a home décor brand that consistently uses botanical motifs across its fabrics builds a consistent look and feel.

Stay flexible with market trends

Trends in fashion, crafts, and homeware change fast. Small batch fabric printing lets you order 10–50 meters instead of hundreds, so you can test a new trend with low risk. If it works, scale up later.

Reduce costs and inventory risk

Traditional wholesale often requires large commitments. Digital printing offers low MOQ fabric printing, which lowers the barrier to entry for startups. You can release new products without fear of leftover stock.

Why Fabric Printing Matters for Small Businesses

Stand out with unique designs

Big brands can flood the market with mass-produced items. Small businesses, however, win through differentiation. Custom fabric printing lets you develop one-of-a-kind patterns, limited editions, or seasonal designs that make your products instantly recognizable.

Strengthen brand identity

Consumers connect with brands through visuals. A signature print can help customers remember your label. For example, a home décor brand that consistently uses botanical motifs across its fabrics builds a consistent look and feel.

Stay flexible with market trends

Trends in fashion, crafts, and homeware change fast. Small batch fabric printing lets you order 10–50 meters instead of hundreds, so you can test a new trend with low risk. If it works, scale up later.

Reduce costs and inventory risk

Traditional wholesale often requires large commitments. Digital printing offers low MOQ fabric printing, which lowers the barrier to entry for startups. You can release new products without fear of leftover stock.

Wholesale Fabric Printing vs. Small-Batch Printing

Not sure which route to choose? It depends on your stage of growth.

| Option | Best for | Typical MOQ | Price per meter | Lead time |

|---|---|---|---|---|

| Small-batch / Low-MOQ printing | Startups, limited editions | 1–50 m | Higher | 7–21 days |

| Wholesale fabric printing | Scaling brands, bulk orders | 100–1000+ m | Lower | 2–4 weeks |

👉 Tip: Start with small-batch printing to validate your idea. Once sales are consistent, move into wholesale fabric printing to maximize your margins.

How to Choose the Right Fabric Printing Partner

Picking the right supplier is one of the most important decisions for small businesses. Use this checklist:

MOQ flexibility — Do they allow small test orders (1–20 m)?

Fabric range — Cotton, polyester, organic fabrics, blends.

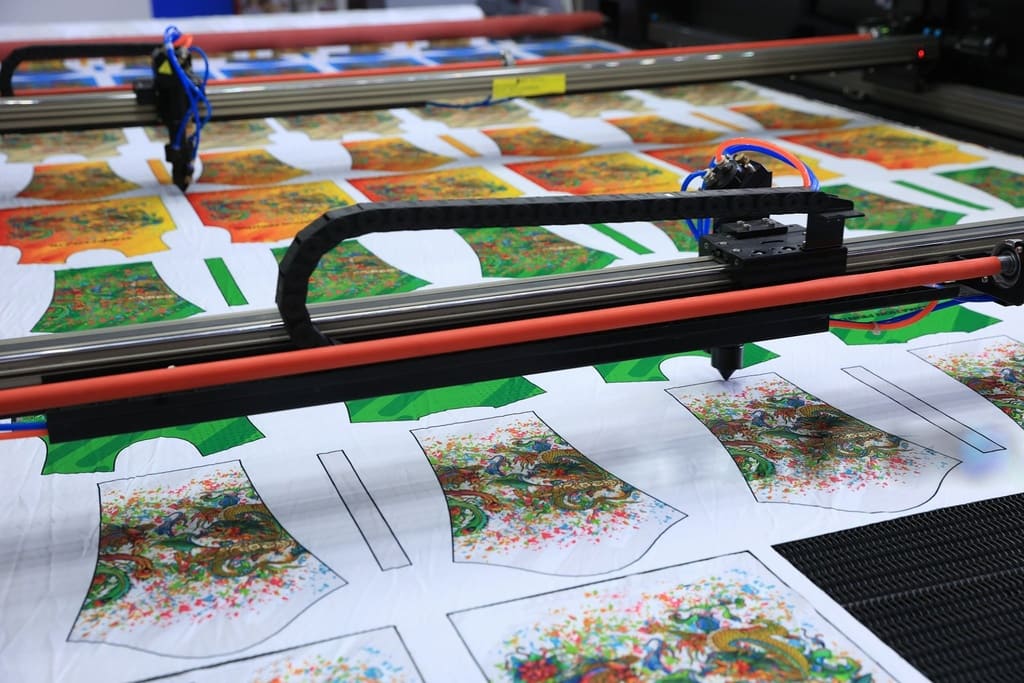

Printing method — Digital printing is best for short runs; rotary is better for very large volumes.

Color accuracy — Ask if they offer test prints or ICC profiles.

Turnaround time — Check average lead times for swatches, small orders, and wholesale.

Transparent pricing — Avoid hidden setup or color-change fees.

Shipping options — Do they ship globally with tracking?

Sustainability — Look for Oeko-Tex or GOTS certified fabrics if eco-friendly production is important.

Communication — Good English support and fast responses save time.

Samples — Always order swatches or test prints before committing.

⚠️ Red flags: vague lead times, no clear MOQ policy, refusal to send samples, or prices that seem “too good to be true.”

Benefits of Fabric Printing for Small Brands

Faster product testing — Order 10–20 meters, launch quickly, and collect feedback.

Better margins later — Scale proven products with wholesale orders.

Brand differentiation — Build a strong visual identity with custom patterns.

Eco-friendly options — Water-based inks and organic fabrics appeal to conscious consumers.

SKU flexibility — Offer seasonal, limited-edition, or made-to-order designs.

Reduced waste — Low-MOQ means no excess inventory stuck in storage.

Practical Step-by-Step Plan

Here’s how a small brand can go from design idea to bulk production:

Step 1: Prepare your design files

File format: PNG, TIFF, or PDF.

Resolution: 200–300 DPI at final print size.

Color: Use sRGB for previews, CMYK/ICC for print.

Repeat & bleed: Export seamless tiles for patterns.

Step 2: Order swatches

Choose 3–5 fabrics.

Test print your design in 1–2 meters.

Check color accuracy, texture, and fabric feel.

Step 3: Run a small-batch test

Order 10–50 meters.

Use it for sample products, photos, and test sales.

Collect customer feedback.

Step 4: Analyze results

If products sell well, refine designs.

Adjust scale, repeat size, or fabric type.

Step 5: Scale to wholesale

Move to 100–500 meters for bulk savings.

Negotiate shipping and payment terms.

Reorder consistently once products are proven.

FAQs

Q1: What is the minimum order for small-batch fabric printing?

Most digital fabric printers allow 1–50 meters, making it affordable for startups.

Q2: How long does fabric printing take?

Swatches: 1–2 weeks. Small-batch: 1–3 weeks. Wholesale: 3–8 weeks.

Q3: Can I get eco-friendly printed fabrics?

Yes. Many suppliers offer organic fabrics and Oeko-Tex certified inks.

Q4: Which file formats should I use?

Most suppliers accept PNG, TIFF, and PDF. Always check their file guidelines.

Q5: Is digital printing suitable for wholesale?

Yes. Digital printing scales well for small to medium runs, though rotary may be cheaper for extremely large volumes.

Conclusion

For small businesses, fabric printing offers a way to bring creative ideas to life without huge upfront costs. Start with swatches, grow with small-batch orders, and scale into wholesale fabric printing once your products have proven demand. This flexible approach reduces risk, strengthens brand identity, and builds a foundation for long-term growth.

👉 Ready to try? [Order your fabric swatches] and explore our [custom fabric printing services]. Start small, test the market, and scale with confidence.