Custom fabric printing has become an essential solution for designers, brands, and DIY creators who want to print your design on fabric with precision and flexibility. However, the final print quality depends heavily on one key factor: fabric selection.

In this guide, we’ll explain how to print on cotton, linen, and canvas, while also covering other popular printable materials like muslin and vinyl. You’ll learn how different fabrics react to ink, which printing methods work best, and how to choose the right material for your project.

If you’re new to custom textile printing, you can start by exploring our step-by-step process on how it works.

Understanding Printable Fabrics: Why Material Matters

Not all fabrics absorb ink the same way. Fiber composition, weave structure, and surface texture all influence color vibrancy, durability, and wash performance. Choosing the right base fabric is the foundation of successful custom fabric printing.

At JCWTextile, we work with a wide range of natural and blended fabrics. You can view available materials anytime on our fabrics.

Cotton Fabric Printing: The Most Versatile Choice

Cotton is one of the most popular materials when brands want to print your design on fabric. Its natural fibers absorb ink efficiently, producing sharp details and vibrant colors.

Why Cotton Works So Well for Printing

Excellent ink absorption

Smooth surface for fine details

Soft, breathable, and skin-friendly

Cotton fabric printing is widely used for:

Apparel and fashion textiles

Home décor (pillows, curtains, bedding)

Craft and DIY projects

Cotton is compatible with digital printing, screen printing, and reactive dye techniques, making it ideal for both small-batch and bulk production.

How to Print on Linen Fabric

Linen fabric offers a more natural, textured appearance compared to cotton. If you’re looking for an organic, premium feel, learning how to print on linen is essential.

Key Characteristics of Linen Printing

Slightly coarse weave enhances natural aesthetics

Ink absorption is lower than cotton, requiring optimized settings

Best suited for soft, earthy color palettes

Linen fabric printing is commonly used for table linens, curtains, upholstery, and lifestyle brands focused on sustainability.

According to Textile World, linen’s fiber structure makes it breathable and durable, but printing requires precise ink control to maintain clarity and color balance.

Printing on Canvas Fabric: Built for Strength and Style

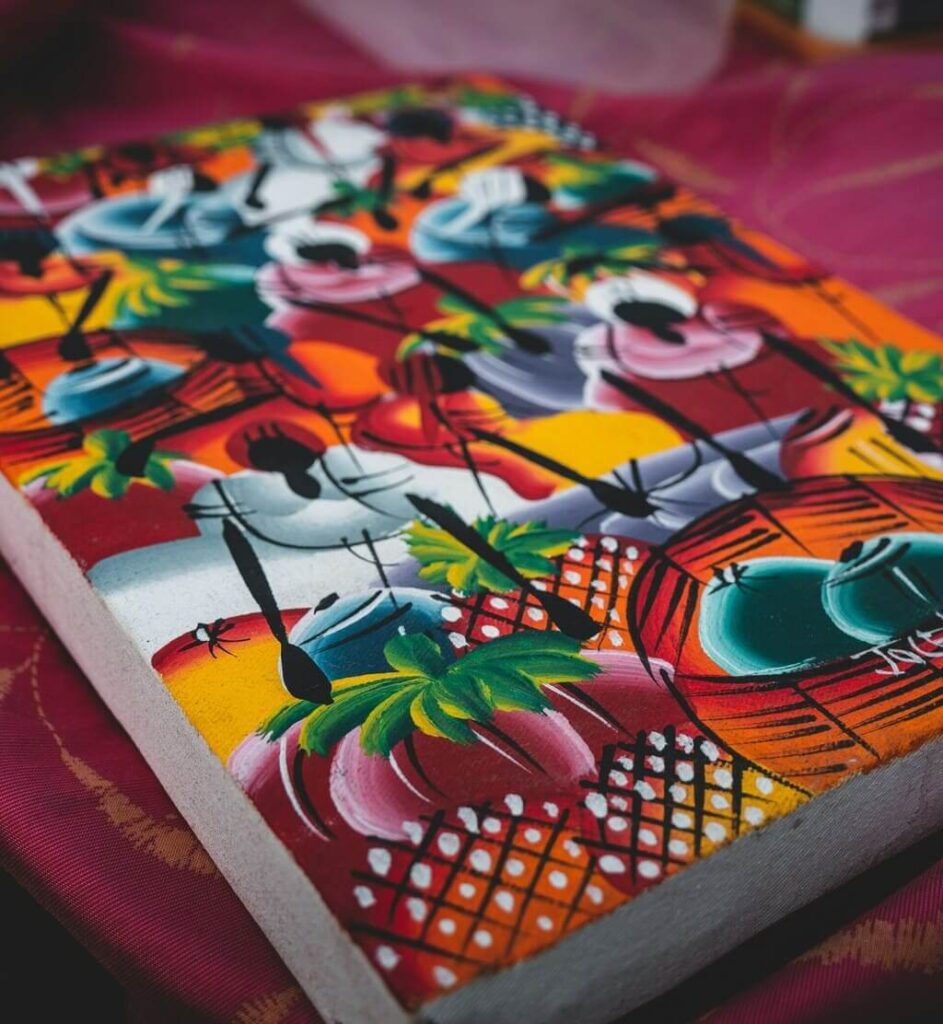

Canvas is a heavy-duty fabric known for durability and structure. When brands want bold, long-lasting designs, printing on canvas fabric is often the best solution.

Benefits of Canvas Fabric Printing

Thick weave supports rich, saturated colors

High durability for repeated use

Excellent for functional and decorative products

Common applications include:

Tote bags and backpacks

Wall art and decorative panels

Outdoor and promotional items

Modern digital printing technology makes it easier than ever to print canvas fabric with consistent quality. The Spoonflower Blog also highlights canvas as one of the most reliable materials for high-impact printed designs.

Printing on Muslin Fabric: Lightweight and Practical

Muslin is a loosely woven cotton fabric that’s widely used for sampling, prototyping, and lightweight applications. Many designers choose to print muslin fabric during early development stages.

When to Use Muslin

Pattern testing and garment mockups

Photography backdrops

Lightweight apparel and linings

While printing on muslin can result in slightly softer edges due to its open weave, it remains an economical and practical option for many textile projects.

Can You Print on Vinyl Fabric?

Vinyl fabric differs significantly from natural textiles. While it’s possible to print vinyl fabric, the process requires specialized techniques such as UV printing or heat transfer rather than traditional textile inks.

Typical Uses of Printed Vinyl

Bags and accessories

Upholstery and marine applications

Protective or waterproof products

As noted by Business of Fashion, vinyl and synthetic materials continue to evolve with new surface-printing technologies, expanding creative possibilities beyond traditional fabrics.

Fabric Printing Methods Explained

Understanding printing techniques helps you match the right process with the right fabric.

Digital Fabric Printing

Ideal for custom designs and short runs

Excellent for cotton, linen, canvas, and muslin

Supports high detail and color accuracy

Screen Printing

Best for large volumes and solid colors

Cost-effective for bulk orders

Works well on cotton and canvas

Print-on-Demand Fabric Printing

No inventory pressure

Perfect for startups and designers

Easy way to print your design on fabric without large upfront costs

You can learn more about how these methods work at design your fabric.

How to Choose the Right Fabric for Your Design

When selecting a printable fabric, consider:

End use: apparel, home décor, accessories, or commercial products

Design complexity: fine details vs. bold graphics

Durability needs: washability, abrasion resistance, outdoor use

If you’re unsure, our fabric guides on the blog provide in-depth comparisons to help you make the best choice.

Common Fabric Printing Mistakes (and How to Avoid Them)

Some frequent issues include:

Choosing a fabric incompatible with your design

Ignoring color differences between screen and fabric

Skipping sampling before bulk production

Understanding fabric behavior early can save time, cost, and production errors.

Conclusion: Start Printing Your Design on the Right Fabric

Whether you want to print on linen, print canvas fabric, or experiment with muslin and vinyl, choosing the right material is the key to achieving professional results.

By understanding fabric characteristics and printing methods, you can confidently print your design on fabric that meets both aesthetic and functional requirements.

👉 Ready to bring your ideas to life? Start your custom project today at design your fabric, or explore available materials at our fabric.

📚 Frequently Asked Questions (FAQs)

Q1: What is the best fabric to print your design on?

The best fabric to print your design on depends on your application. Cotton is ideal for apparel and home textiles, linen offers a natural textured look for décor, and canvas works best for durable products like bags and wall art.

Q2: Can you print your design on fabric at home?

Yes, simple designs can be printed at home using heat transfer paper or inkjet-compatible fabrics. However, professional fabric printing delivers better color accuracy, durability, and wash resistance—especially for cotton, linen, and canvas.

Q3: How do you print on linen fabric without losing detail?

To successfully print on linen, digital textile printing with calibrated ink density is recommended. Because linen has a textured weave, high-resolution artwork and proper color profiling help maintain detail and consistency.

Q4: Is printing on canvas fabric suitable for detailed designs?

Yes. Modern digital printing technology allows highly detailed graphics when printing on canvas fabric. Thicker canvas works best for bold designs, illustrations, and long-lasting applications.

Q5: What printing method is best to print your design on fabric?

Digital fabric printing is the most versatile method to print your design on fabric, especially for custom orders and small batches. Screen printing is more suitable for large volumes with simple color designs.

Q6: Can muslin fabric be printed professionally?

Yes. Printing on muslin fabric is common for samples, prototypes, and lightweight applications. While muslin absorbs ink well, its loose weave may produce a softer print compared to tightly woven cotton.

Q7: Can vinyl fabric be printed the same way as cotton or linen?

No. Vinyl fabric requires specialized printing methods such as UV printing or heat transfer. Traditional textile inks used for cotton, linen, or canvas are not suitable for vinyl surfaces.